Setup

[Graphics import] [Tool table] [Tool change] [Program behavior] [Program appearance]

Back to [GUI] [Menu items]

Graphics import

[Graphics import] includes all settings regarding graphics import and G-Code generation (by 'Text creation', 'Simple shape' etc.).

[Path import] [G-Code generation] [G-Code modification] [Use cases]

Path import

Settings regarding import of SVG, DXF, HPGL, CSV, etc. files.

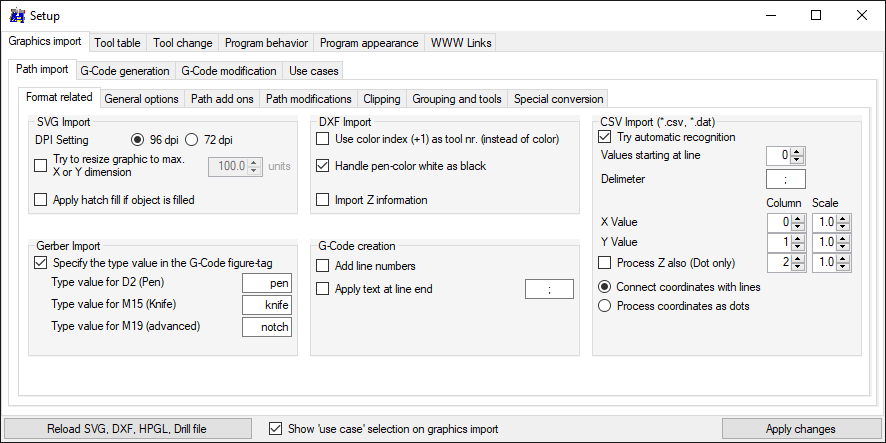

Format related:

E.g.

- SVG: automatically resize to a specific value (to fill your drawing area)

- SVG: automatically apply hatch-fill if fill color is set

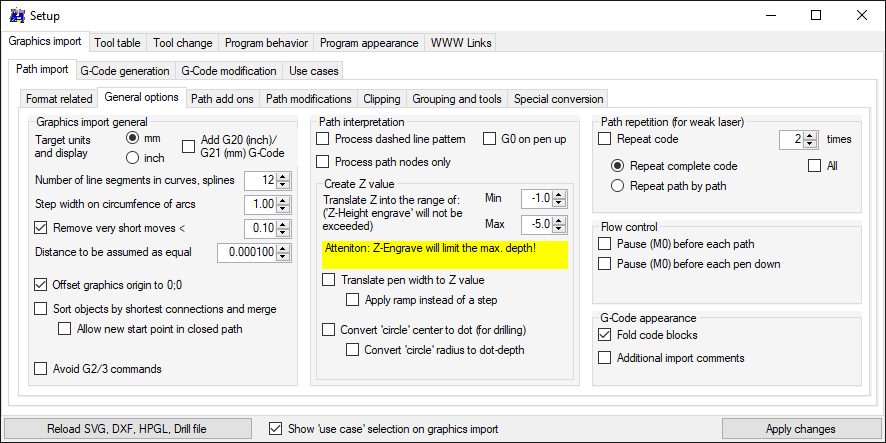

General options:

Accuracy, sorting, how to handle specific patterns, path repetitions.

G-Code appearance

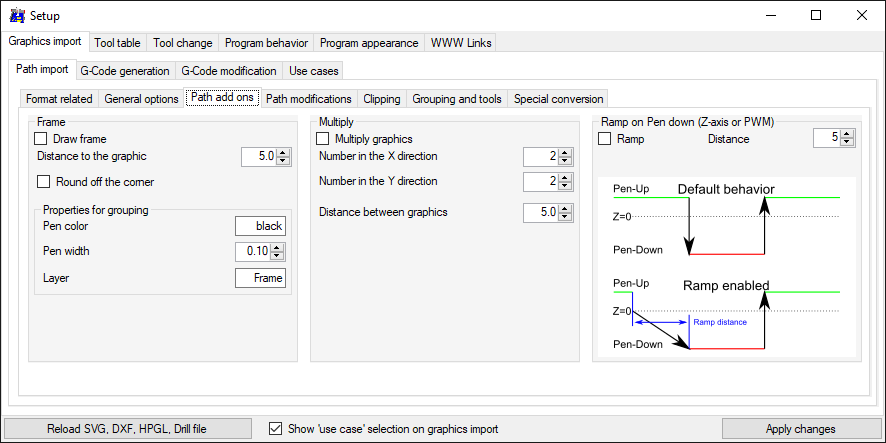

Path add ons:

- Add a frame

- Multiply the imported graphics

- Add a ramp on Z motion

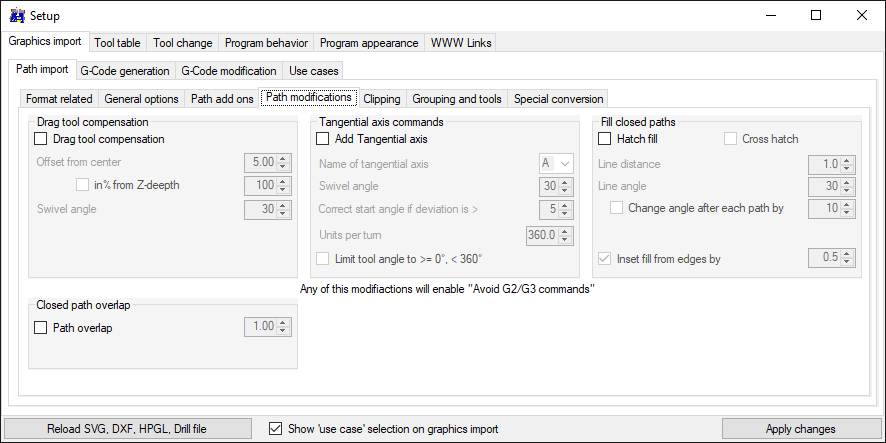

Path modifications:

- Drag tool compensation (for knife or brush) Example 'Drag tool compensation'

- Path overlap on closed paths (laser cutting) Example 'Path overlap'

- Add tangential axis commands (for tangential knife):

- Hatch fill of closed paths Example 'Hatch fill'

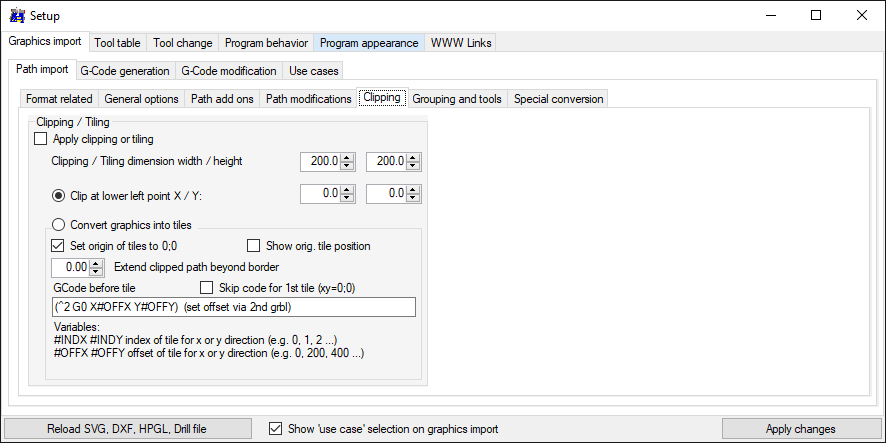

Clipping, Tiling:

Clipping: only process a selected area of the imported graphics.

Tiling: divide the graphics into tiles and process them one by one, apply commands before a tile to feed the material,

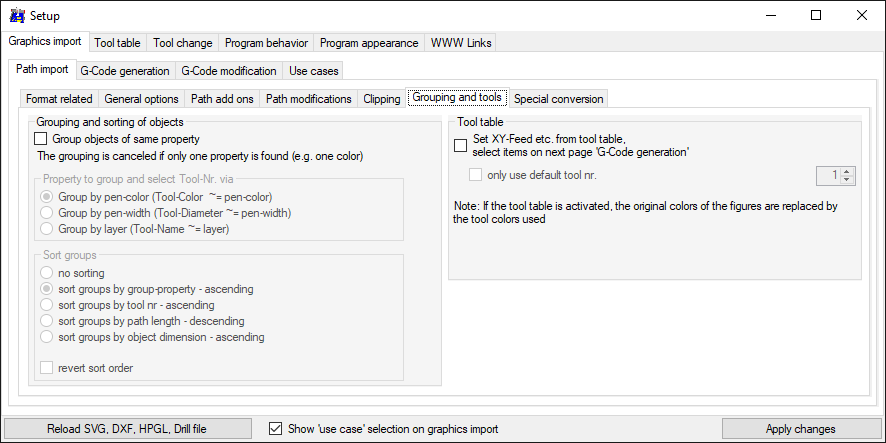

Grouping, Tool table use:

Grouping: group the graphic objects by pen-color, pen-width or layer.

Tool table use: get selected properties (checkboxes 'from tool table' in G-Code generation) from the current tool table.

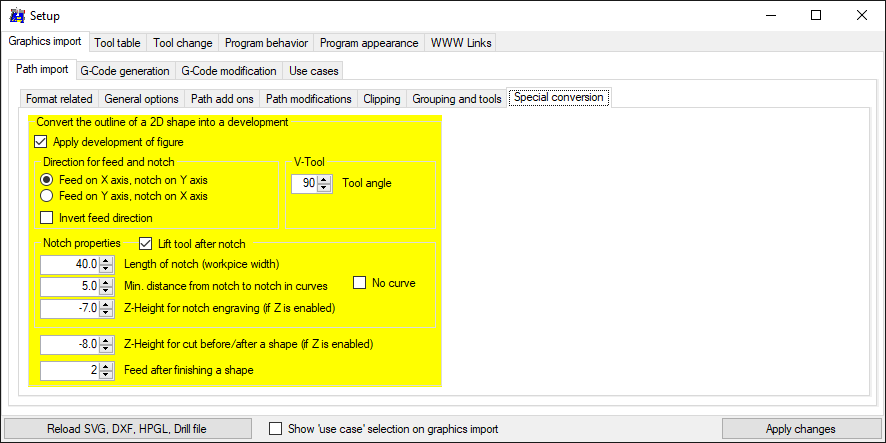

Path development:

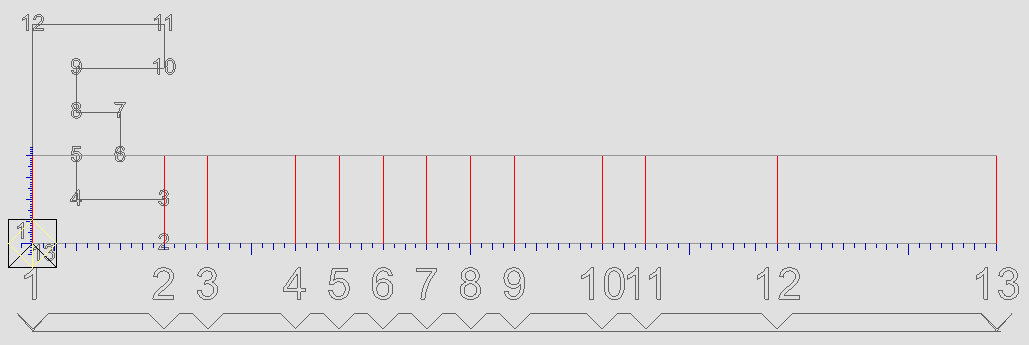

Example: character "E" with the given settings:

Red lines shows the tool path,gray objects are just for information.

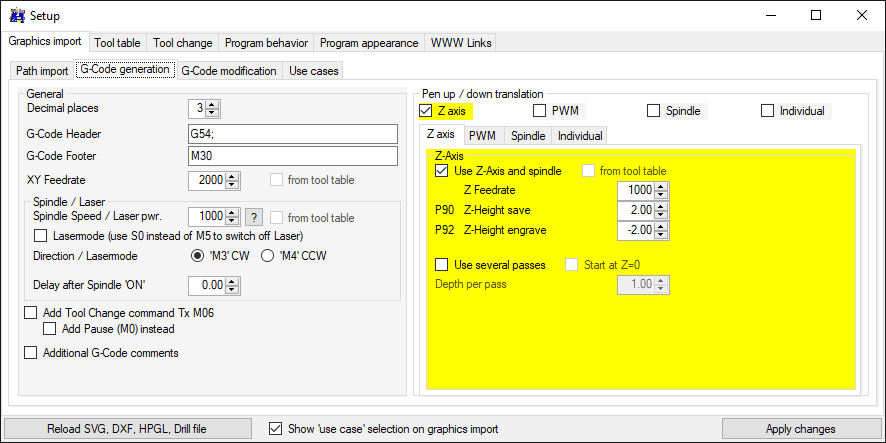

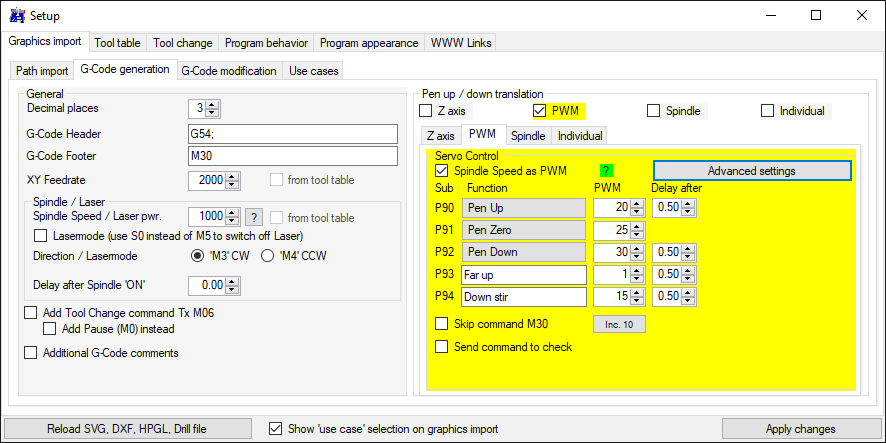

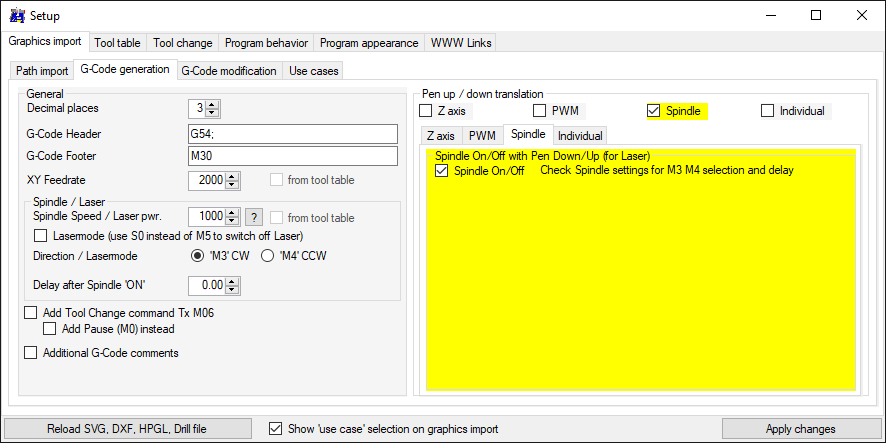

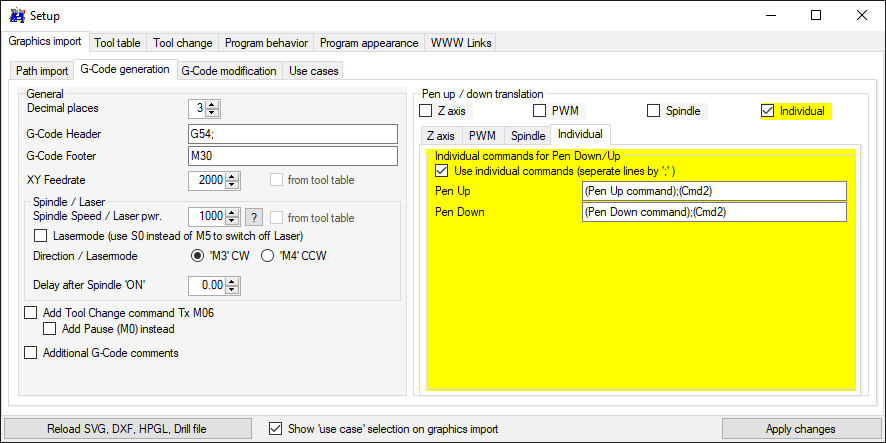

G-Code generation:

Set decimal places (grbl max.: 3 for mm, 4 for inch), code header and footer for individual comands, XY-feed rate, spindle speed, Tool change.

Translate Pen-up/-down commands into Z axis commands

Translate Pen-up/-down commands into PWM (pulse-width-modulation) values to control a RC-servo.

Note: a special grbl version is needed to control a servo.

Translate Pen-up/-down commands into spindle (or laser) on / off commands

Translate Pen-up/-down commands into individual commands

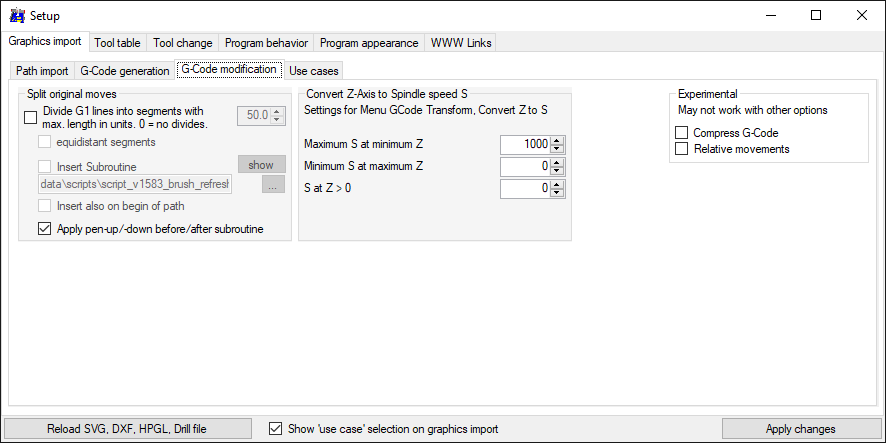

G-Code modification:

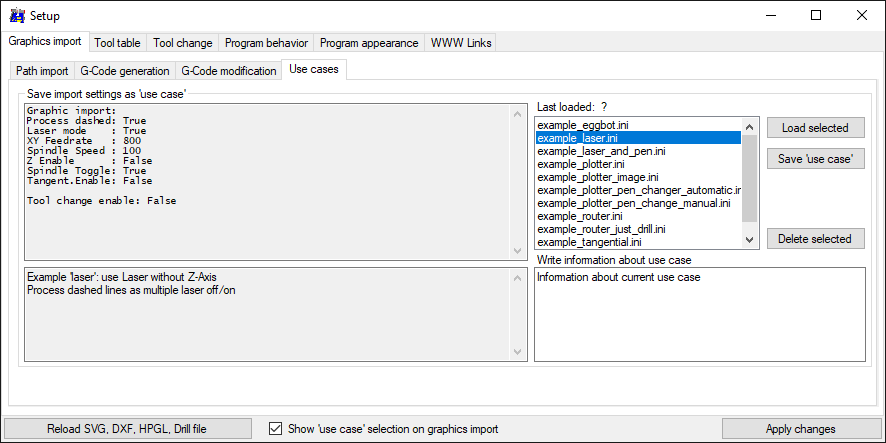

Use cases:

Use cases contains a reduced amount of saved machine settings (ini-file) to do a quick setup of the settings.

Also a saved machine-setup [Menu - File - Export machine settings] can be used as a use-case, when copied to the usecase folder (check [Menu - About] for the current location).

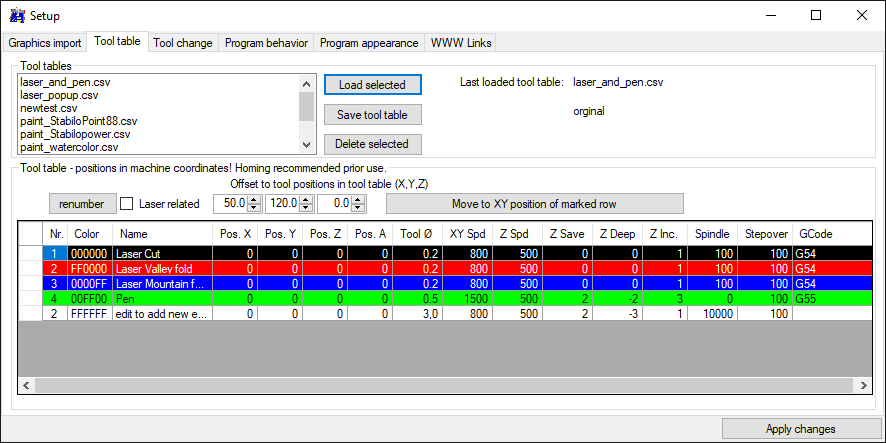

Tool table:

Settings, which are related to specific pen-color or pen-width, if tool table is in use.

Examples: [Laser and Pen] [Manual pen change] [Automatic pen change]

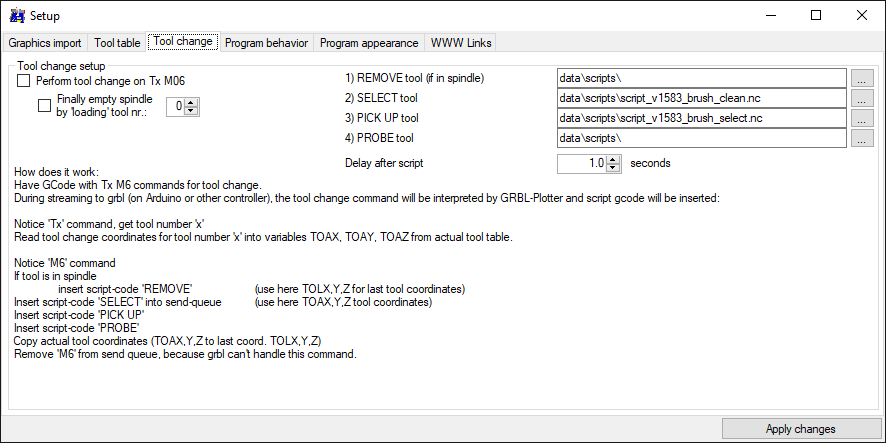

Tool change:

Assign scripts, which will be performed on M06 command. See also 'Automatic pen change'

See also: Tool change how it works

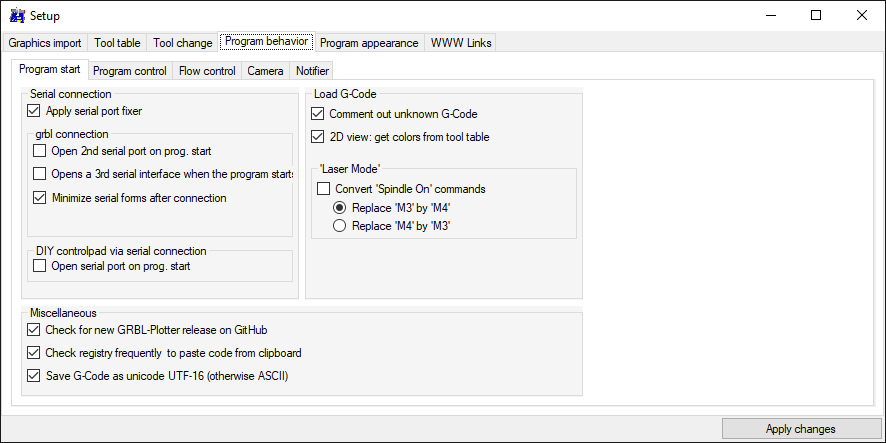

Program behavior:

Settings regarding grbl comunication, grbl settings, G-Code loading and saving, camera shape recognition and Notifier

Program start

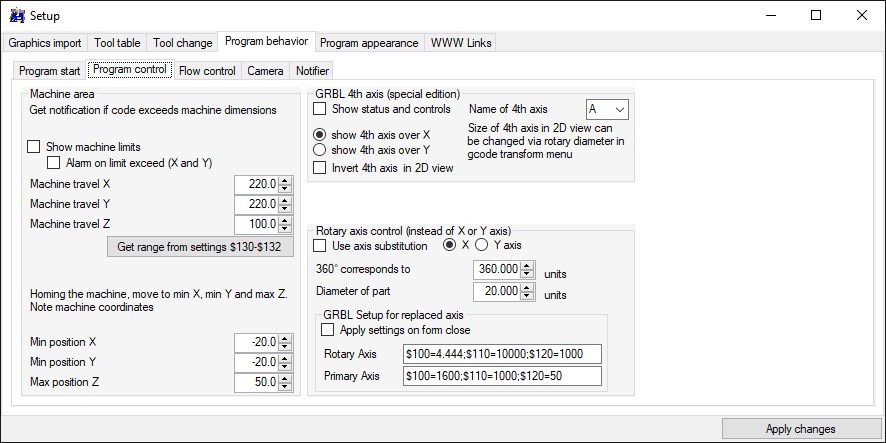

Program control

Machine limits: get warnings if allowed machine area will be left.

Grbl 4th axis: set name and display of 4th axis.

Rotary axis control: use X or Y as rotary axis and setup

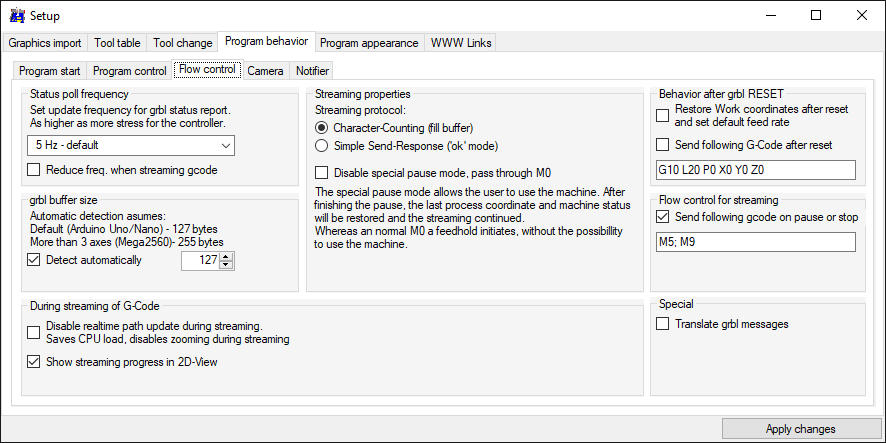

Flow control

Status poll frequency: frequency of grbl position update

Grbl buffer size: depends on used hardware and grbl version

Streaming properties: modes, check here character counting

During streaming of G-Code: setting which could reduce CPU load for older computers

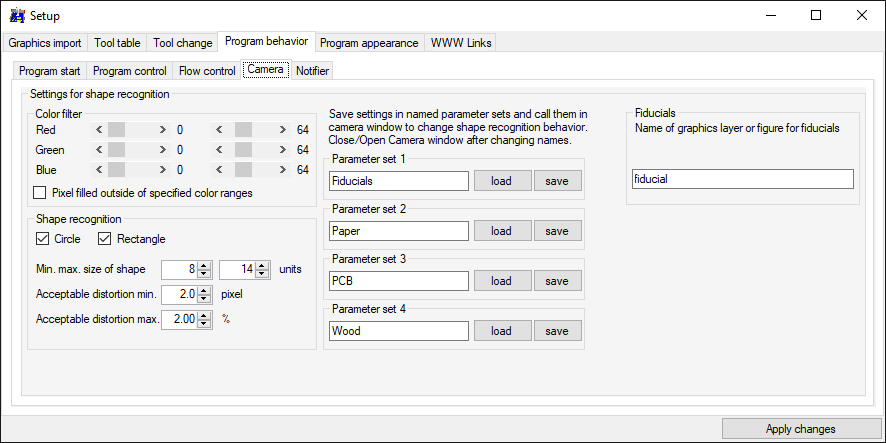

Camera

Settings for shape recognition in camera form - for automatic fiducial correction

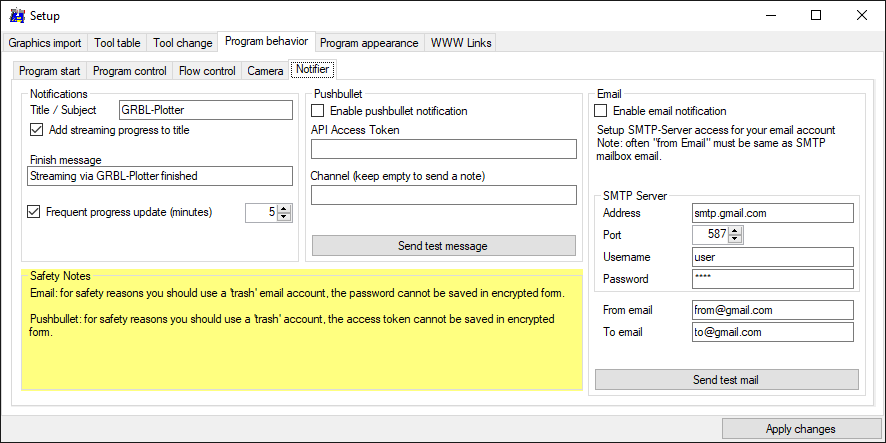

Notifier

Get updates of your streaming progress via pushbullet or by email

Program appearance:

Settings regarding the Graphical User Interface, Hot-Keys, Game pad, Joystick...

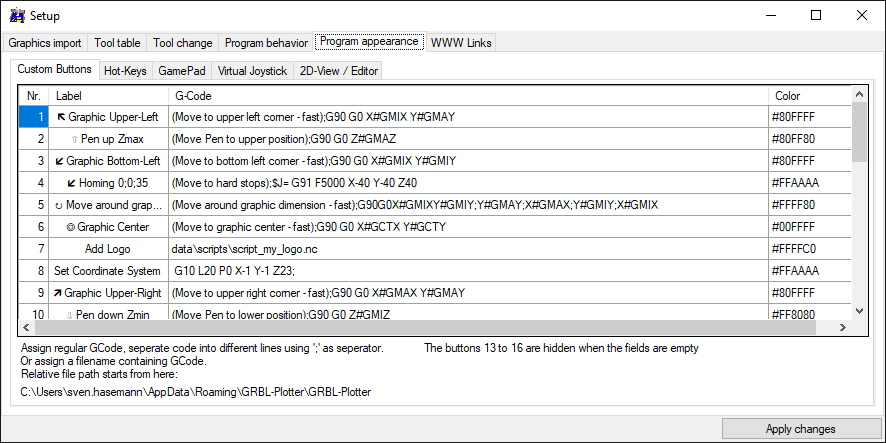

Custom buttons

Custom buttons can also be changed via right-click on button

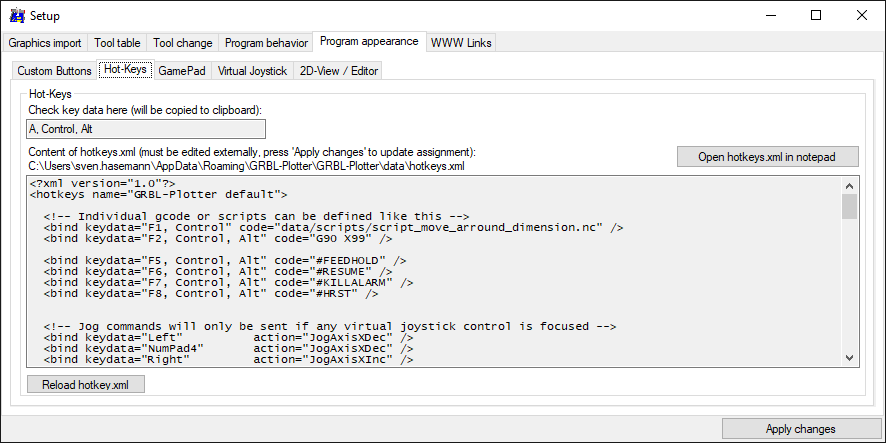

Hot keys

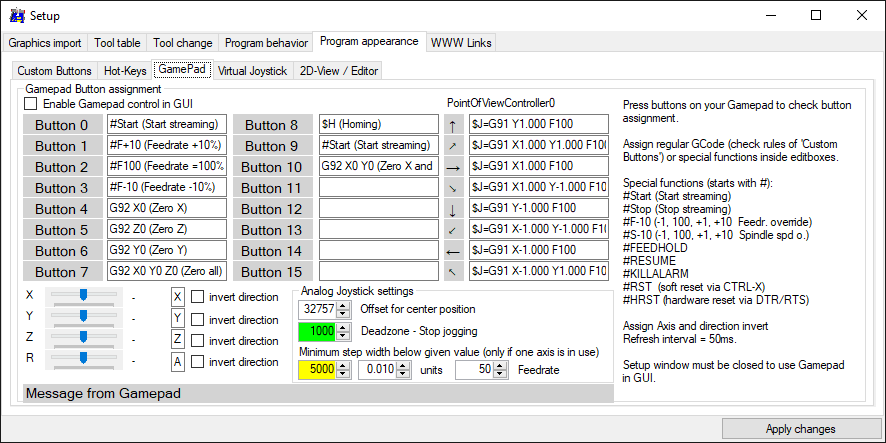

Game pad

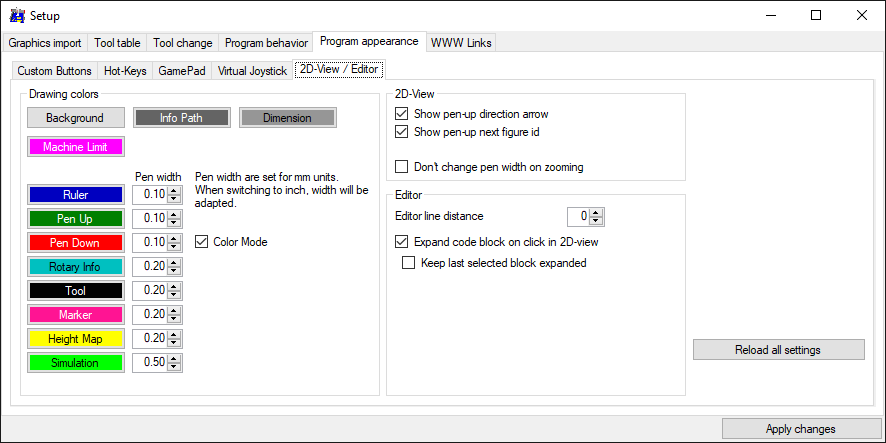

Virtual joystick

2D view