Setup program behavior

[Setup import] [Setup import extensions] [Setup G-Code generation] [Setup Program behavior] [Setup Program apperance]

Back to [GUI] [Menu items]

Program behavior

Settings regarding grbl comunication, grbl settings, G-Code loading and saving, camera shape recognition and Notifier

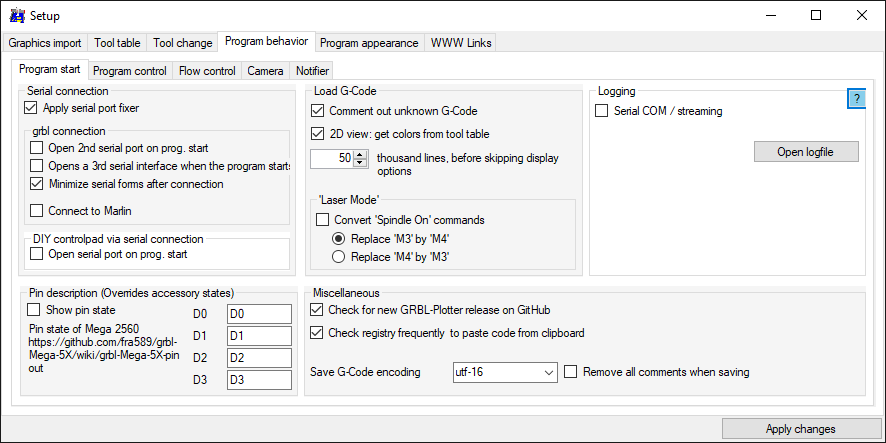

Program start

Serial connection

- Apply serial port fixer: starts extra program code to reduce serial COM problems.

- Open 2nd serial port on prog. start: also open a serial window for a 2nd grbl

- Open a 3rd serial interface: also open a serial window for a 3rd interface

- Minimze serial forms after connection: minimize all COM winodws after successful connection.

- Connect to Marlin: force Marlin comunication (sometimes hard to detect automatically)

- DIY controlpad - Open serial port on prog. start: also open a serial window for a 4th interface

Load G-Code

- Comment out unknown G-Code: Sometimes external G-Code starts with '%' which is an error for grbl.

- 2D view get colors from tool table: if the G-Code doesn't contain grbl-Plotter specific XML tags, it will be tried to assume colors by loaded tool table and G-Code Z-axis values.

- ...thousand lines, before skipping display options: a huge amount of G-Code slows down grbl-Plotters behavior. If given number will be exceed, e.g. the pen-up paths and path-starts will not be drawn anymore.

- Laser Mode / Convert spindle on commands: replace M3 by M4 commands or vice versa

Pin description

- Show pin state: The grbl-Mega-5X firmware also supports digitial inputs, which can be shown in the GUI with the given names.

Miscellaneous

- Check for new GRBL-Plotter release on GitHub: on program start, check for new program version on GitHub.

- Check registry frequently to paste code from clipboard: useful if you are using scripts from [Menu - G-Code Creation - Extensions]. A script will set a registry key after generating G-Code, grbl-Plotter is polling this key and loads the G-Code. More info: Registry

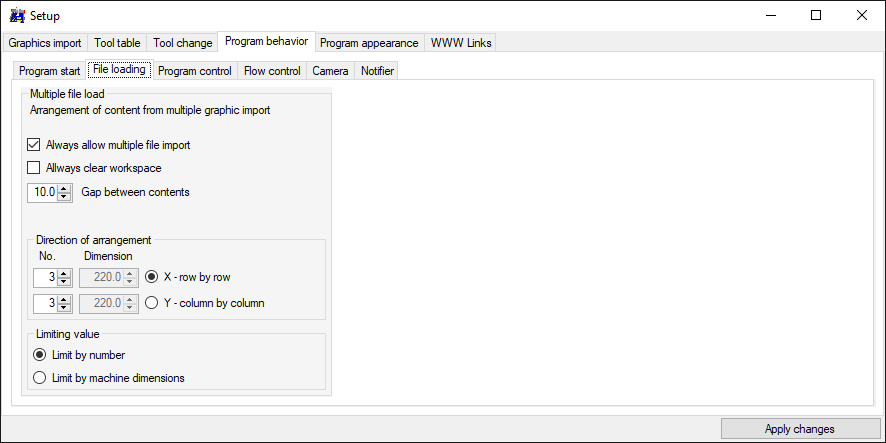

Program behavior - File loading

Via drag & drop multiple files can be imported in GRBL-Plotter. This options handle how to arrange the imported objects. They can be arranged line by line or column by column.

- Always allow multiple file import: always allow, or only if "Add imported graphic to 2D view" is enabled.

- Always clear workspace: clear 2D view before importing new graphics.

- Gap between contents: gap in units between objects in X and Y direction.

- Direction of arrangement: Set direction and max. amount of objects per direction. Or limit amount by machine area size.

- Limiting value: Select if limitation appears by number of objects or by machine limits.

Program behavior - Program control

Load machine defaults on connect

Via the $I-command, a custom string can be read or set. If an INI-file with this string-name is available in the folder data\usecases, it can be loaded automatically on hardware-connect.

Note: the loading of the INI file happens only after 1st connect on program-start or after switiching from an other grbl-hardware, not after a reset.

- Set: If grbl hardware is connected, you can set the custom string in the edit-box and press 'Set'. Wait some seconds for the write and read action, to see the resulting string (some characters are not allowed by grbl).

- Test ini file: the main-settings of the INI-file will be shown - like on 1st hardware connection.

- Open file: the INI-file content can be viewed and changed in the windows text-editor.

- Save settings: the actual settings will be saved in an INI-file with the given filename to data\usecases - reday for use (INI-file has same content as stored via Menu - File - Export machine Settings).

- Accessory run times: shows the duty cycle in ms of the outputs for spindle (laser) M3/M4, flood M8 and mist M7.

Perhaps useful to determine the remaining lifetime of a laser.

Accessory run times

The overall operation time of spindle/laser (M3, M4), flood (M7) and mist (M8) will be summed up, and can be check here, e.g. for maintenance reason.

Machine area

- Show machine limits: enables the limits in the 2D-view

- Alarm on limit exceed: a desired move will be checked if limits will be exceed, before executing.

- Machine travel range for X,Y and Z: the limited travel range

- Get range from settings: if the controller is connected, the values can be read out

- Min position X,Y and Z: needed to calculate the absolute limit positions

GRBL 4th axis

Rotary axis control

Use the X or Y axis as rotary axis

Automatically restore grbl settings.

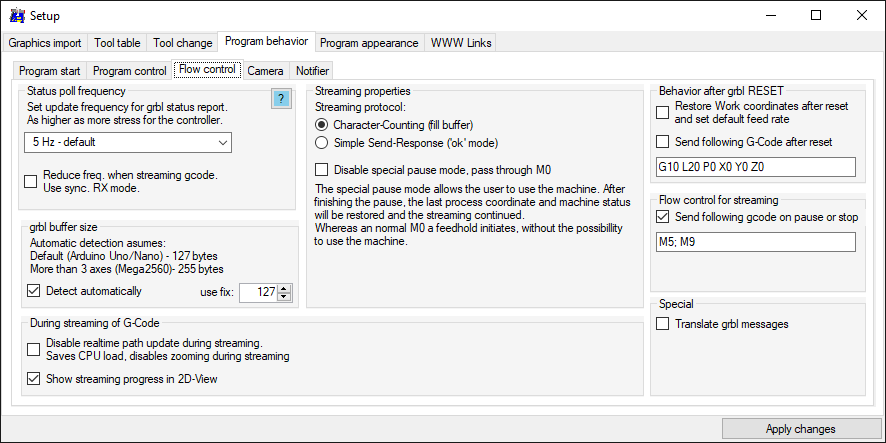

Program behavior - Flow control

Flow control

Status poll frequency: frequency of grbl position update

Grbl buffer size: depends on used hardware and grbl version

Streaming properties: modes, check here character counting

During streaming of G-Code: setting which could reduce CPU load for older computers

Behavior after grbl reset: Restore last work coordinate (after switching on the controller) or send given code after reset.

Flow control for streaming: Send the given code on streaming-pause, e.g. to switch off the spindle and cooling.

Translate grbl messages: Translates the controller messages to the selected language.

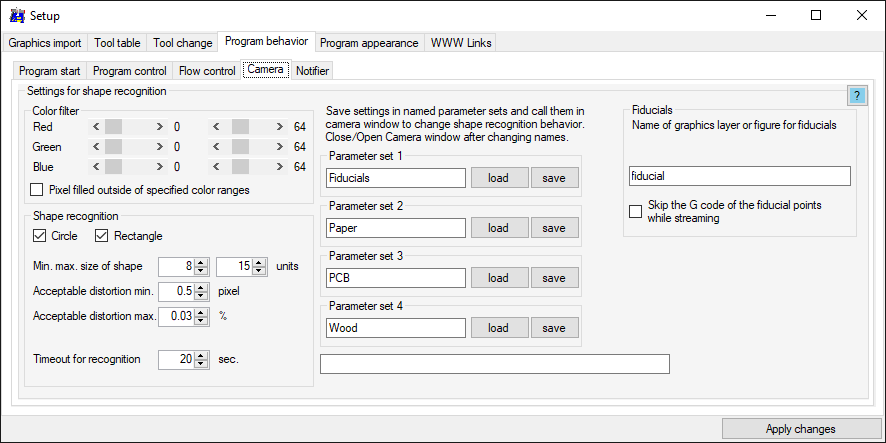

Program behavior - Camera

Settings for shape recognition in camera form - for automatic fiducial correction

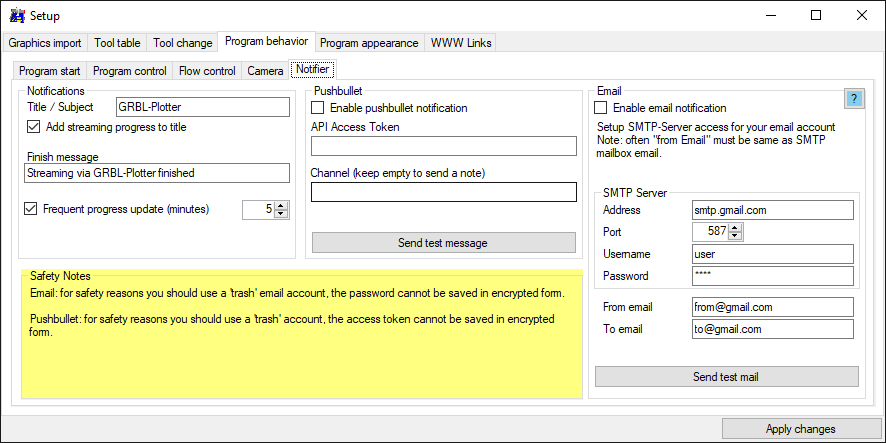

Program behavior - Notifier

Get updates of your streaming progress via pushbullet or by email