Probing

G-Code Creation: [Text] [Barcode] [Image] [Simple shapes] [Jog path] [Extensions]

Workpiece: [Probing] [Height map]

Machine: [Laser tools] [Coordinate systems] [DIY Control] [Camera] [Process automation]

back to [Menu]

Probing uses the G38.3 command to detect the contact of the tool with the workpiece. By default, grbl detects a contact to ground on Pin A5, which means, the cutter / probing-tool is connected to ground (because it is perhaps already connected to ground via the spindle and support) and the touch-plate is connected to Pin A5.

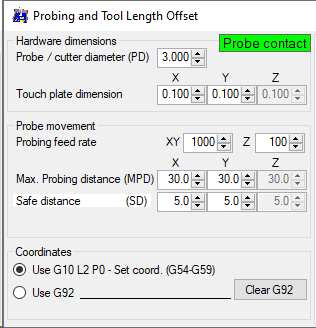

General settings are:

- Probe / cutter diameter: needed to calculate offsets, if 'Set tool center as zero' is enabled.

- Touch plate dimension: thickness of touch-plate or aluminum-tape, needed to calculate offsets.

If a conducting workpiece is used, these values needs to be set to zero. - Probing feed rate: speed of the probe when moving toward the edge.

- Max. Probing distance: range / distance to move to find the edge.

- Save distance: distance from edge to move to finally - after resetting the coordinates.

Must be higher than touch plate thickness. - Use G10 L2 P0: sets the actual coordinate system after successful probing.

- Use G92: set the coordinate system offset instead.

The field 'Probe contact' indicates if the probe-input is triggered or not.

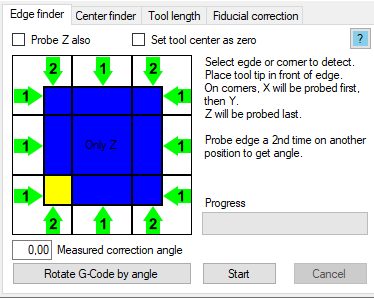

Edge finder

With the edge finder an edge in X, Y, X and Y and additionally in Z can be found and used to set the work coordinates to zero.

If more then one edge should be found, the order is as visible in the graphics: first '1' then '2', finally Z.

Place the tool tip in front of the workpiece in the same area in which the arrow tip is shown in the graphic.

If an edge is found two times (vertical or horizontal) an angle will be calculated, which can be applied to the G-Code shown in the 2D-view of the main GUI.

Click on a tile to get 'Start' enabled.

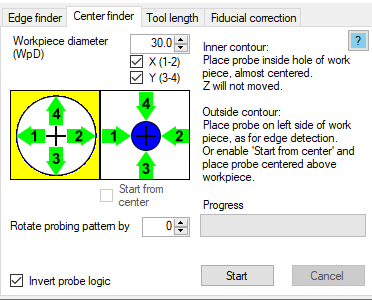

Center finder

With the center finder, the center of a drill or round workpiece can be found.

Workpiece diameter: needed if the outside contour is selected, to move above the workpiece far enough from position 1 to 2 to 3 to 4.

Start from center: first move to the left, then down, to be able to start with step '1'.

Rotate probing pattern: the pattern to find the edges can be rotated.

Invert probe logic: needed for fiducial recognition, using an inductive proximity sensor on a metal coin to find the center.

Click on a tile to get 'Start' enabled.

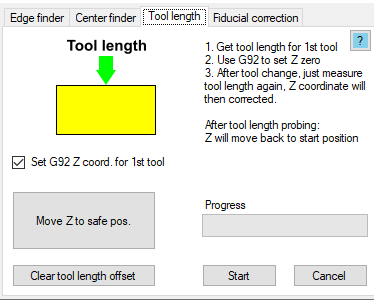

Tool length

Tool length correction is a bit tricky:

- 1st get the tool length of the first tool

- Then zero the Z position via G92 as needed

- Start work

- After a tool change, measure tool length of new tool

Fiducial correction

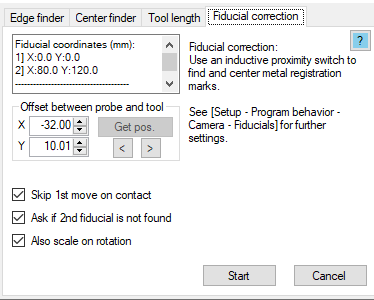

If a graphic with fiducials is imported, the fiducial coordinates are displayed in the text box.

In my application the real fiducials are metal coins/washers, which can be detected with an inductive proximity sensor.

See also Application examples - Fiducial correction.

Offset between probe and tool: set the tool-position relativ to the probe-position (set to 0;0). Use the 'Center finder' to set probe-pos = 0;0, then move the tool centric above the coin and press "Get pos." to take over the actual coordinates.

Skip 1st move on contact: if the probe is already triggered, the assumption is that the probe is already above the correct fiducial, the move to the 1st fiducial will be skipped.

Ask if 2nd fiducial is nor found: after moving to the 2nd fiducial it is expected that the probe is triggered. If not, the user gets a change to move the probe manually, via the joystick, to the correct position.

Note: not available if 'Fiducial correction' was started from 'Process automation'.

Also scale on rotation: when the 2nd fiducial is found, the information will be used to rotate the G-Code in the 2D-view but can also be used for scaling (stretching or compressing the G-Code).